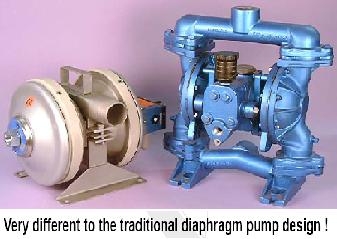

The "inside out" concept allows fluid to pass between the diaphragms, directly through the centre of the pump. Air pressure operates on the outside.

Longer lasting diaphragms:

A significantly reduced stroke length allows use of thicker/stronger PTFE diaphragms as standard. Nitrile, Viton and EPDM are also available.

Faster Maintenance:

Fifteen minutes to change diaphragms by the removal of just one nut and without disconnecting the pump from the pipework.

Lower cost spares:

Less than half the quantity of spare parts than any equivalent pump and interchangeability of most air parts between different series of pumps.

No Lubrication:

Aunique patented air system incoporating a bolt on spool valve, including manual override buttons, eliminates costly internal air mechanisms and mid position stall normally asociated with double diaphragm pumps.

Greater inherent safety:

Plastic parts are kept within metal containment and potential leak paths are reduced to a minimum. Even under ATEX conditions pumps can be maintained 'in the zone' up to Zone I using anti-static PTFE-faced diaphragms.

ATEX:

Flotronic's unique One-Nut range of air-driven double diaphragm pumps comply fully with the electro-static hazard requirements defined in ATEX Group II, Category 2, effective 1/7/03.